Swamp coolers contain a motor that powers a small fan. There are several types of swamp coolers with different capacities of motors. The motor of your swamp cooler can easily be fixed if there is a problem with its electrical power or technical functionality.

In this section, we discuss how the swamp cooler motor works, its installation, and wiring. This article provides all the information you require about the swamp cooler’s motor.

Swamp Cooler Motor:

Swamp coolers have relatively small motors in their bodies. In swamp coolers, there are several types of motors with different capacities and power ranges. Most often, 1/3 to 3 horsepower motors are used. The other heavy motors require more than 220 volts, while these can efficiently be run on 115/120 volts.

How To Fix Swamp Cooler Motor:

You can quickly fix the swamp cooler motor problem if you have the right tools and instructions. The following sections describe the most common issues that swamp cooler motors encounter and how to resolve them.

Make Sure You Thoroughly Check The Motor:

When you are trying to fix your motor, the first step you need to take is to inspect the motor and identify the actual problem. You need to check the wiring and power supply first, and then the belt and bearing of the motor.

[rank_math_rich_snippet id=”s-f465bd37-e40f-4417-a63d-cdc8eedbe7eb”]

You do not need to replace the motor of your swamp cooler if there is a problem with the wiring or any other minor issue, but if there is a problem with the motor, you might need to replace it.

Remove Old Belt:

After identifying the actual problem, and if the motor is malfunctioning, the motor needs to be unplugged. A wrench will make things much easier for you when you remove the belt from the motor. It is easy to remove the belt and use that measurement to purchase a new one.

Maintain The Motor:

As you remove the belt from your motor, ensure that the bearing is in good condition so you can replace it if it needs to be replaced. If there were an issue with the belt, you would notice it when removing the belt from the motor.

If there is a problem with the rewinding or any other complex issue, you need to hire a professional to work on the motor.

Insert New Belt And Fit The Motor:

After maintaining the motor, Replacing the old belt is as simple as removing the old one. Make sure it’s snug before you secure it. Make sure the belt is seated correctly and that the mounts are tightened to hold it in place.

Test It

Test your motor before you install it in the cooler to make sure it is working properly? If you check and the motor works properly, you should fit your motor in the swamp cooler.

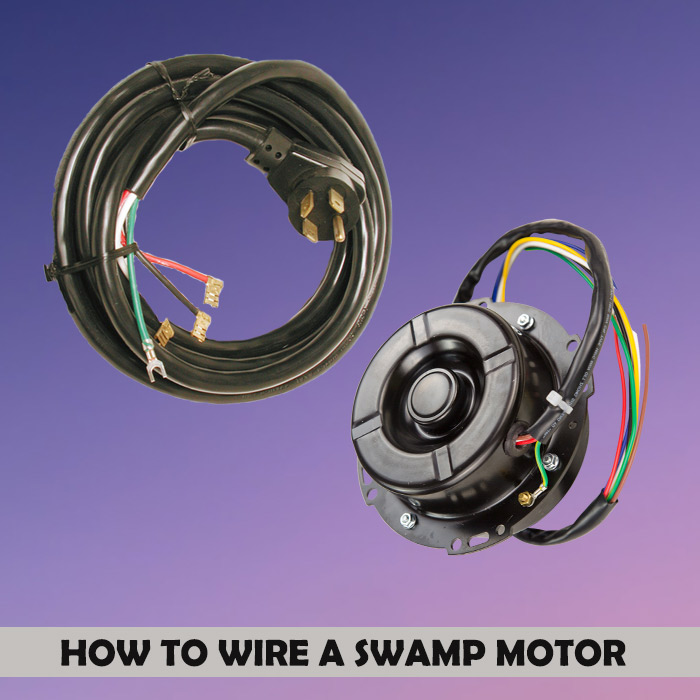

How To Wire A Swamp Cooler Motor And Pump:

You should follow the manufacturer’s instructions when connecting wires to terminals. You can choose between a single or two-speed motor for regular household use. The swamp cooler motor is usually pre-fitted with four short wires, which must be connected to the control circuit for the cooler and the 120-volt circuit. All connections should be soldered and sealed with shrink-wrap insulation kits. It is most common to connect the colour-coded lines, as shown in the following steps.

The green wire in the 120-volt circuit should be connected to the ground.

The red wire in the control circuit should go to the low fan speed.

The black wire should be connected to a 120-volt high fan speed.

A 120-volt circuit should have a white wire connected to neutral.

1 3 Hp Swamp Cooler Motor:

A motor’s power can be measured in horsepower. In the swamp cooler, we can use a motor with a power range of 1/3 – 3. If the horsepower increases, the speed and electricity consumption will increase as well.

Electricity is needed for swamp coolers to function. A voltage supply provides that amount, but the actual amount is measured in amperes, or “amps.”. More powerful coolers may need higher amperages, possibly up to 15 amps. For smaller coolers, 1 amp is sufficient.

What Size Of Motor Should I Use For My Swamp Cooler:

If you are making a DIY swamp cooler, then the size of the motor depends on the body of the cooler. If you have a small plastic body for the cooler as a reservoir, you can have a small motor in your cooler.

Choosing the right motor size and capacity for your swamp cooler depends on your needs. However, when you replace your swamp cooler motor, you must purchase the same motor size as the existing one. In such a case, you will not be able to replace the motor, and if you do, you will have problems with the cooler.

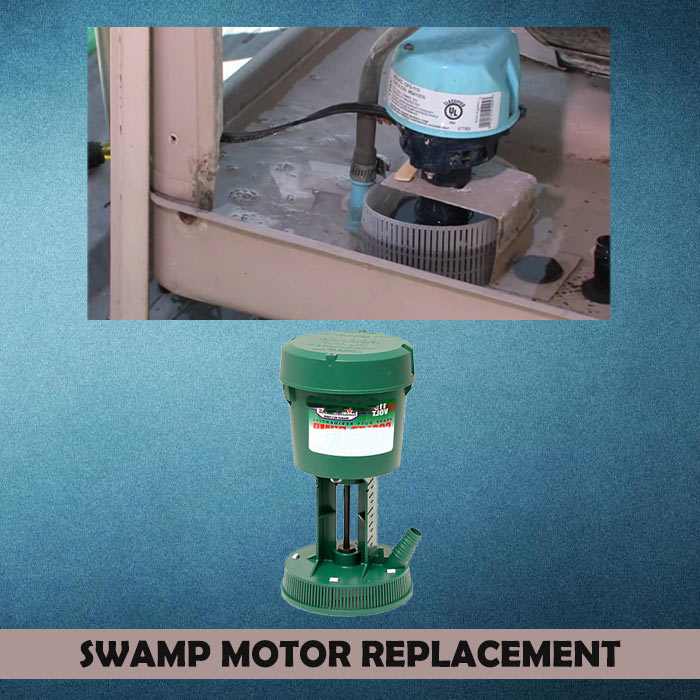

Swamp Cooler Motor Replacement:

A handy person may be able to replace a swamp cooler motor themselves.

For the motor to be unbolted, the side panels must be removed, and some essential tools will be required.

Please make sure you take pictures when removing any bolts or wiring in case you need to refer back to them later.

Be sure the unit is also off by turning the power off.

Replacement Of Motor Costs:

You can expect to pay $50 to $600 when replacing a motor. Motors for large, more advanced systems tend to be more expensive. Their price is largely determined by their size and their maintenance requirements. The cost of replacing a motor increases if it requires more maintenance and many parts need to be replaced.

Swamp Cooler Motor Troubleshooting:

Your cooler will work well for a long time with regular maintenance, but there will be parts that wear out and stop working as with all electrical appliances. Unfortunately, they usually happen at the worst time. This type of cooler does not have a complex system. The coolers are reliable. Troubleshooting an evaporative cooler motor can help you get back to normal faster in your home or business. The following are a few things you should check when the unit won’t turn on.

Before you do anything, make sure that the wiring and voltage inputs are correct. Something is wrong with the wiring. This problem must be fixed. In some cases, the exact voltage is not coming due to an electrical failure, which results in the motor not functioning correctly.

Another thing to check is the bearing of the motor. It is necessary to replace the bearing if the motor bearing is faulty.

In a typical household setting, the motor should be 120-volt. This information is often printed or embossed on a nameplate; if not, contact the manufacturer’s customer support staff with the plate number and ask for the information. In addition, discover how your swamp cooler motor’s wires function based on their color.